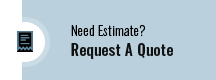

PCB RFID Tag Manufacturer

50 INR/Piece

Product Details:

- Surface FR4 PCB

- Memory Size 128 bits EPC memory

- Frequency 860-960 MHz

- Reading Distance Upto 8 meters (depends on reader)

- Thickness 1.2 mm

- Application Inventory management, asset tracking, supply chain logistics

- Crafts Laser engraving, silk screen printing

- Click to View more

X

PCB RFID Tag Manufacturer Price And Quantity

- 200 Number

- 50 INR/Piece

PCB RFID Tag Manufacturer Product Specifications

- Inventory management, asset tracking, supply chain logistics

- 1.2 mm

- -40C to +85C

- UHF RFID

- Yes

- RFID passive tag

- FR4 PCB

- Impinj Monza R6

- 55 mm x 18 mm x 1.2 mm

- 860-960 MHz

- 128 bits EPC memory

- PCB RFID Tag

- Upto 8 meters (depends on reader)

- Impinj Monza R6

- Laser engraving, silk screen printing

PCB RFID Tag Manufacturer Trade Information

- Cheque

- 2 Week

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

Product Description

RFID PCB Tags, which is highly admired due to its superb strength, good quality and highly durable in nature. We made the same by utilizing best quality required components with the help of innovative technology under the visionary of our experts. It is best choice to use for searching, identification and tracking purposes. Our valued clients can avail this RFID PCB Tags from us within the promised time frame.Versatile Mounting & Superior Durability

Designed for real-world application flexibility, our PCB RFID tag supports adhesive, screw, or rivet mounting. The robust FR-4 epoxy glass fiber construction and waterproof, anti-metal, and dust resistant features equip it for harsh environments without compromising performance.

Reliable Performance & Longevity

Achieve consistent operation with up to 100,000 read/write cycles and data retention for 10 years. The Impinj Monza R6 chip ensures efficient UHF communication (860-960 MHz), while its resistance to extreme temperatures guarantees uninterrupted use across various industries.

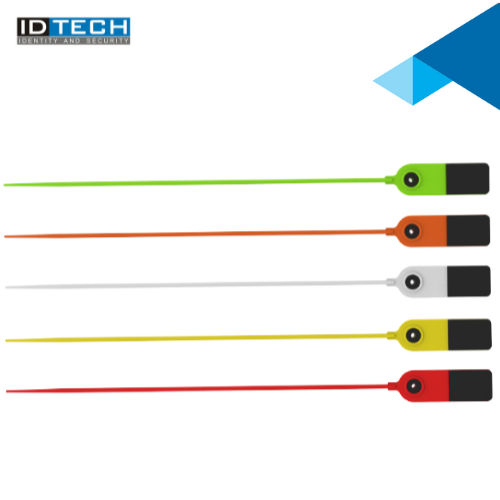

Customization For Every Need

Choose from laser-engraved numbering, multiple surface finishes, color options, and variable sizes to match your project requirements. Each tag can be uniquely coded, maximizing compatibility and traceability in your inventory or asset tracking systems.

FAQs of PCB RFID Tag Manufacturer:

Q: How can I mount the PCB RFID Tag for secure installation?

A: The PCB RFID Tag can be mounted using adhesive, screws, or rivets, allowing secure placement on a wide variety of surfaces. This flexibility supports deployment in diverse environments and operational setups.Q: What are the benefits of using FR-4 epoxy glass fiber for RFID tags?

A: FR-4 epoxy glass fiber provides excellent mechanical strength, electrical insulation, and resistance to moisture and chemicals. These characteristics make the tag highly durable, waterproof, and suitable for industrial environments.Q: Where are these PCB RFID Tags commonly used?

A: These tags are widely utilized in inventory management, asset tracking, and supply chain logistics, especially in industries where harsh conditions, long-range reading, and data durability are essential.Q: What customization options are available for the RFID tags?

A: We offer laser engraved numbering, custom coding, selectable surface finishes, various colors, and sizes tailored to your specific requirements, providing optimal tracking and identification solutions.Q: How long does the PCB RFID Tag retain stored data, and how many read/write cycles does it support?

A: The tag guarantees data retention for up to 10 years and supports approximately 100,000 read/write cycles, ensuring longevity and reliable performance throughout its service life.Q: What is the process for ordering custom PCB RFID Tags from your company?

A: To order, simply contact us with your specifications for coding, color, surface type, and size. We will guide you through the design, production, and delivery process, ensuring your tags meet all operational needs.Q: What makes these RFID tags virus proof, and how does it benefit the user?

A: The non-porous FR-4 surface resists microbial contamination and allows easy sanitization, minimizing infection risks. This feature is particularly beneficial for healthcare, food logistics, and other hygiene-sensitive sectors.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'RFID Tags' category

"We are accepting bulk order quantity only."